Upgrade & Secure Your Future with DevOps, SRE, DevSecOps, MLOps!

We spend hours on Instagram and YouTube and waste money on coffee and fast food, but won’t spend 30 minutes a day learning skills to boost our careers.

Master in DevOps, SRE, DevSecOps & MLOps!

Learn from Guru Rajesh Kumar and double your salary in just one year.

Source:-https://www.healthcarepackaging.com

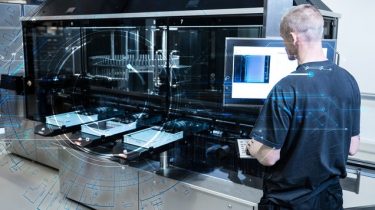

Stevanato Group, a global provider of integrated containment and delivery systems to the biopharmaceutical and life sciences industries, has launched an Artificial Intelligence platform, based on Deep Learning (DL) models, designed to leverage the benefits of human-like decision-making in automatic visual inspection equipment. The platform is made to allow pharma companies to overcome the traditional trade-off between detection rate and false rejection rate, ensuring robust and replicable results. False rejects can be significantly reduced and the detection rate improved, yielding up to 99.9% accuracy, both for particle inspection and cosmetic defects detection.

DL is particularly beneficial when applied to difficult-to-inspect and high-value biotech drugs, as it allows pharma companies to achieve higher productivity while preserving drug integrity. Drugs in the form of suspensions or lyophilized cakes frequently challenge available vision tools, causing misinterpretations of supposed defects. Artificial Intelligence mitigates misclassification and reduces costly re-inspection, says the company.

Through its partnership with Microsoft and the adoption of Microsoft Azure platform, Machine Learning, and AI features, Stevanato Group intends to deliver “smart” equipment compliant with strict pharmaceutical data management and security requirements, while improving inspection performance and reducing costs related to production reparametrization. The company reports the certified cloud-based platform is compliant with U.S. CFR 21 Part 11 and EU GMP Annex 11, meets data integrity needs, and offers advanced monitoring tools such as heat maps and confusion matrix for model performance evaluation.

Incorporating new technologies can be challenging for pharma companies, as it usually requires them to adapt internal processes and invest time and resources. The company provides a team of vision and AI engineers to bring an accurate data analysis service with continuous support for tasks from image collection to model validation.

Key features of the platform include:

* Cloud-based: Data remains online and therefore perpetually available. The certified cloud-based platform that stores images and data can work with any cloud-based system and allows operators to manage images even if they are stored in the server.

* Security: Compliant with U.S. CFR 21 Part 11 and EU GMP Annex 11, the platform enables data sharing in a completely safe environment. Further, multifactor authentication and encrypted communication should ensure complete access control and data security.

* Assistance: Continuous support is available for all platform capabilities throughout the process, assisting pharma companies with a variety of tasks including a labeling assistant tool to optimize timing for classification and new recipe development.

* Monitoring: The platform features a wide range of statistics and visualizations (heat maps, confusion matrix, etc.) for model performance evaluation. Pharma companies should be able to track and monitor all processes through real-time reports.

Starting: 1st of Every Month

Starting: 1st of Every Month  +91 8409492687 |

+91 8409492687 |  Contact@DevOpsSchool.com

Contact@DevOpsSchool.com